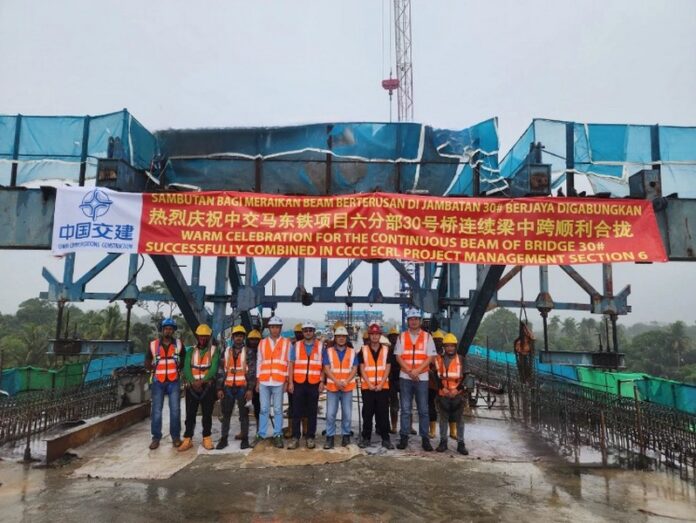

Recently, with the completion of the last cubic meter of concrete pouring poured, the last 108m-long meters continuous beam of the Pahang River Bridge was successfully combined in of the China-Malaysia East Railway CCCC ECRL project was successfully closed.

The Pahang River Bridge spans over Pahang River, the longest river in Western Malaysia, with a total length of about 2.3 kilometers km and a total of 64 spans, which is one of the key and difficult projects of ECRL Project Management Section 6in the six parts of the project. The bridge Bridge is designed with three continuous beams, which span the western fork mouth of the Pahang River, the East eastern fork mouth of the Pahang River and Highway 10. , respectively. The continuous beam is constructed symmetrically by hanging basket casting method in the method of cantilever hanging basket, which has the characteristics of features difficult construction, complicated construction technology and high safety risk.

The continuous beam section of Pahang River is located in the gathering area of Malay Aborigines., Before the construction, which isit was faced with the difficulties of design approval and land acquisition before construction.; During during the construction process, it also faced several challenges, such as the recurrence of COVID-19 and the construction platform was being repeatedly flooded due to repeated epidemics and rising rivers. In the face of difficulties and challenges, the project construction team planned aheadin advance, studied and judged risks, organized and promoted the project construction scientifically, and organized several special meetings on technical solutions to ensure the smooth development of the construction.

The continuous beams of Pahang River Bridge were all closed combined, and successfully opening the beam erection and track laying channel of Section C of Management Section 6six divisions was successfully opened, which laid a solid foundation for the subsequent construction and production of Section C, and also maintained a good momentum for the continuous completion of node construction and production targets of the Section construction and production. The project department will take this as an opportunity to continue to focus on the target of 2024, improve quality and efficiency, and take the lead, fight bravely to and continue to achieve win new victories continually.

vv

vv